Raph Hamelain • February 22, 2026

This blog post is for informational purposes only, explaining the Safety Advocate Program. It is not legal advice or compliance guidance.

TL;DR: The 6 Pillars of Safety

The 6 Pillars of Safety form a practical framework for strong programs: a clear manual, flexible training, Job Hazard Analyses (JHAs), weekly meetings, PPE inspections, and fair enforcement. Together, they make protection consistent and built into daily routines for teams in high-risk trades like solar panel cleaning, window washing, and pressure washing.

If there’s one thing clear from real teams in the field, it’s this: safety works best when it’s simple, consistent, and part of the daily routine. That’s the idea behind the 6 Pillars of Safety—six interconnected tools that address common challenges and create a complete, proactive program.

Let’s break down each pillar.

Pillar 1: A Safety Manual That Gets Used

Most companies have a manual, but it often sits unused because it's hard to find or understand. A good one is clear, accessible (digitally or printed), and serves as a quick reference for onboarding or refreshers—keeping everyone on the same page and setting the foundation for everything else.

Pillar 2: Online Training That Fits Busy Schedules

Training doesn't have to halt work. Flexible modules—short, mobile-friendly and available anytime—help teams build knowledge without losing productivity, while tracking ensures certifications stay current.

Pillar 3: JHAs That Build Hazard Awareness

Job Hazard Analyses help crews pause to identify risks and plan controls before starting work. When done consistently, this pillar makes spotting and mitigating hazards a natural habit—bridging the manual and training into practical, on-the-job action.

Pillar 4: Weekly Safety Meetings That Stay Relevant

Short, focused discussions (or videos) keep safety conversations going without becoming a burden. This pillar addresses current issues, reinforces earlier learning, and maintains momentum across the team.

Pillar 5: PPE Checklists That Prevent Failures

Daily quick checks on gear like harnesses, helmets, and gloves catch wear early—ensuring protection works when needed and meeting requirements like OSHA's PPE standards (1910.132).

Pillar 6: Enforcement Checklists for Consistent Accountability

Fair, documented steps help address violations constructively—focusing on improvement and trend, while reinforcing the value of all the other pillars.

These 6 Pillars of Safety interconnect to create a balanced program: the manual sets clear guidelines, training and meetings build skills, JHAs and PPE checks manage daily risks, and enforcement maintains accountability.

When they become habits, safety feels built-in—teams stay stronger, work flows better, and everyone heads home safe.

As we explore the 6 Pillars of Safety, the first one lays the groundwork for it all. Start here: Pillar 1 - The Safety Manual that supports consistent protection.

This blog post is for informational purposes only, explaining the Safety Advocate Program. It is not legal advice or compliance guidance.

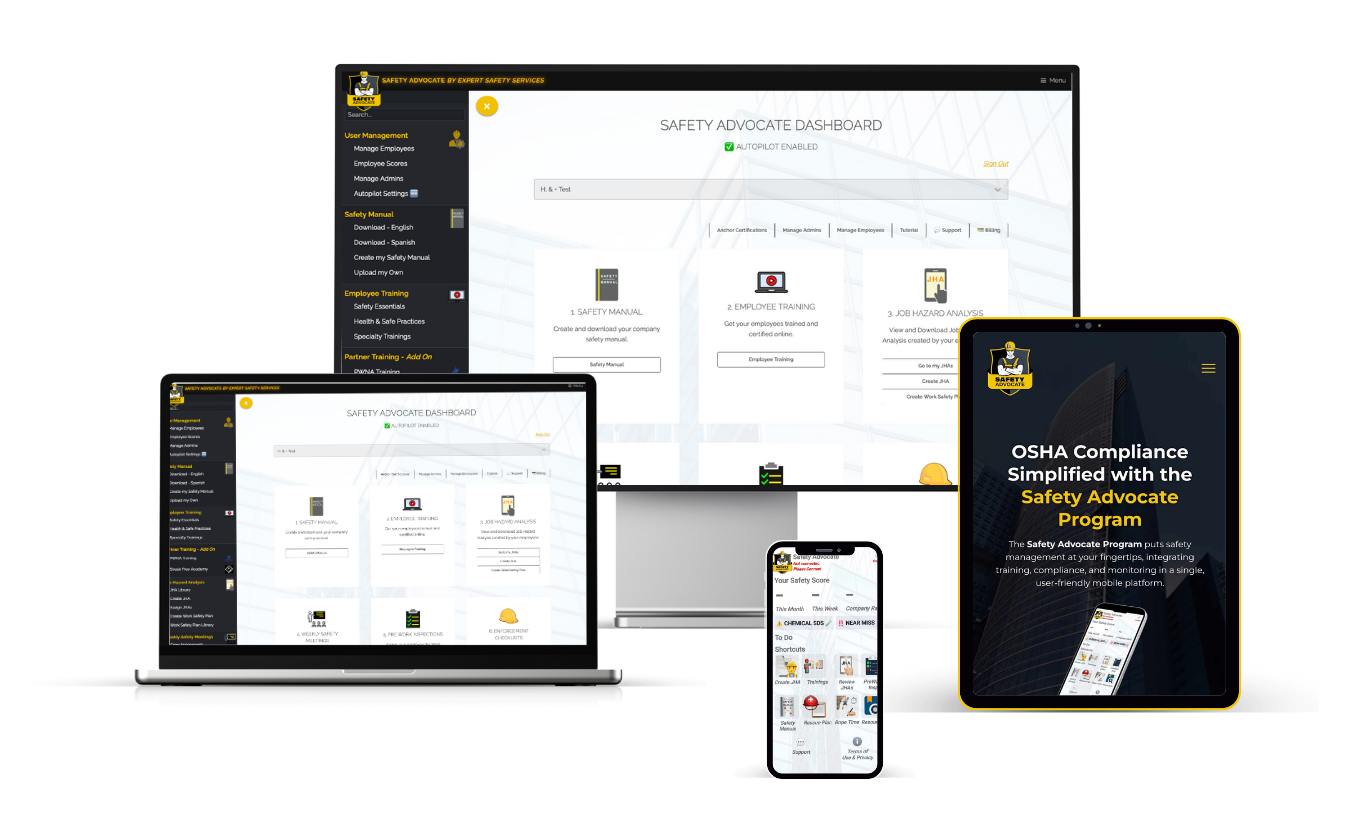

Contact us today to learn more about the Safety Advocate Program.

Contact Us

Featured Articles

This blog post is for informational purposes only, explaining the Safety Advocate Program. It is not legal advice or compliance guidance.